A Big Leap in Energy Efficiency

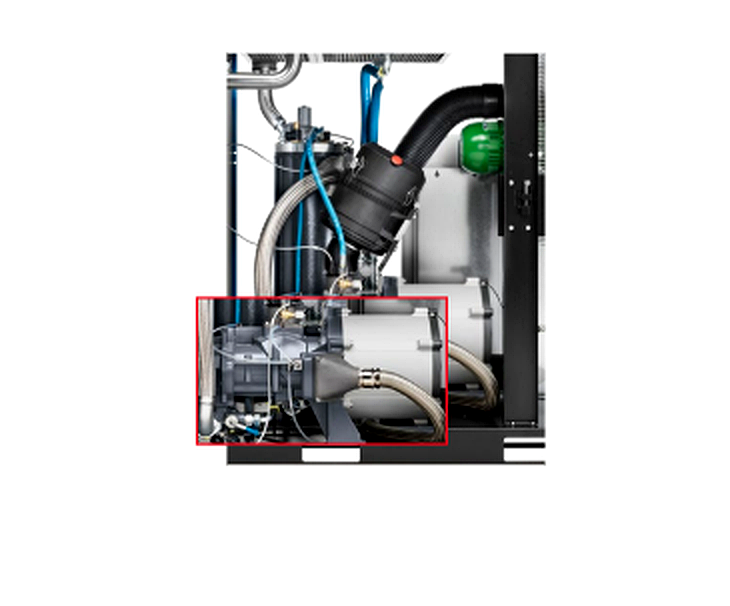

The CPMV iPM Series rotary screw air compressors represent a new generation of energy-efficient compressed air solutions. Integrated permanent magnet motors and inverter-driven technology ensure only required energy is consumed.

- iPM Motor Technology – Superior efficiency at all loads

- Variable Speed Drive – Matches real-time air demand

- 30–35% Energy Savings – Compared to fixed-speed compressors

- Stable Air Output – Smooth pressure for critical processes

- Lower Maintenance – Longer service life

Chicago Pneumatic (CP) is a global leader in the design, manufacture and distribution of high-performance compressors. With a focus on pioneering design, high-impact technology, and durability, Chicago Pneumatic means Customer Value.

Our goal is to deliver best-in-class global service and local support to our customers through a dedicated product portfolio and a strong network of authorized distributors.

Today, CP is a global brand that offers products for countless applications and almost every industry. After all these years, CP still stands for reliability, durability and customer value.

Milestones Roadmap

Key moments across our journey — shown on a continuous road.

Why iPM technology?

Traditional Variable Speed vs. Fixed Speed Technology

- Reduced energy costs with 30–35% in variable demand applications

CPMV iPM vs. Fixed Speed Technology

- Reduce energy costs up to 45% in variable demand applications

- Combined effect of:

- Latest generation Variable Speed Technology

- Highly energy-efficient drivetrain with iPM motor technology

- In-house designed “Screw Element”

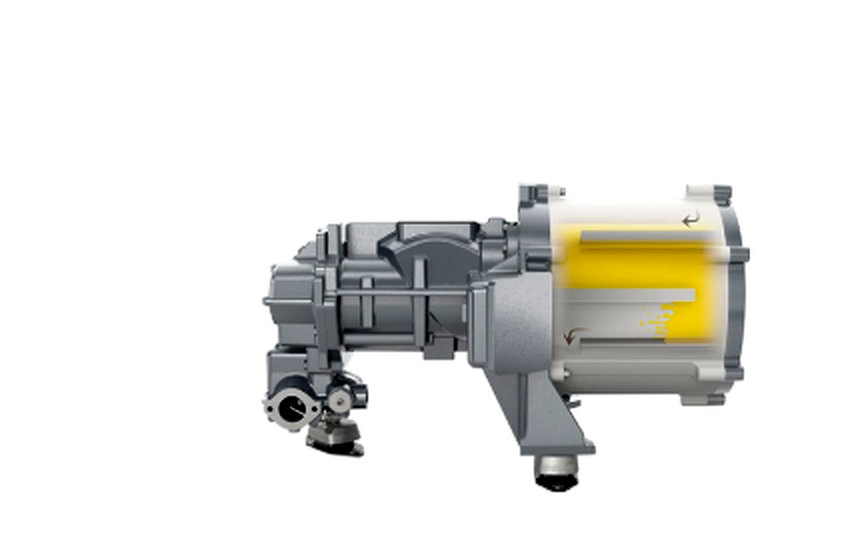

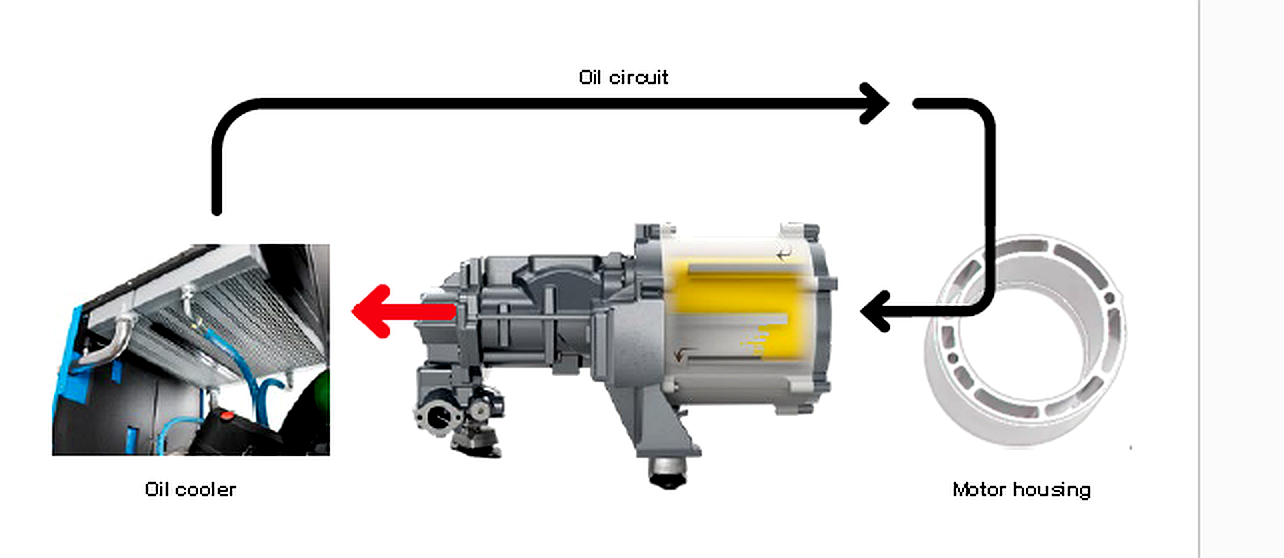

Oil Cooled iPM Motor (Interior Permanent Magnet)

- In-house designed iPM motor

- IE4 Super Premium efficiency (up to 96%–97%)

- Direct drive configuration for enhanced savings

- Latest IP protection class

- Proven oil cooled design for stability

- Horizontal configuration for easier maintenance

- 100% in-house design

IE4 Super Premium Efficiency iPM Motor

Up to 5% energy savings vs. IE2 / IE3 induction motors in CPMV — higher efficiency across operating conditions for lower running costs.

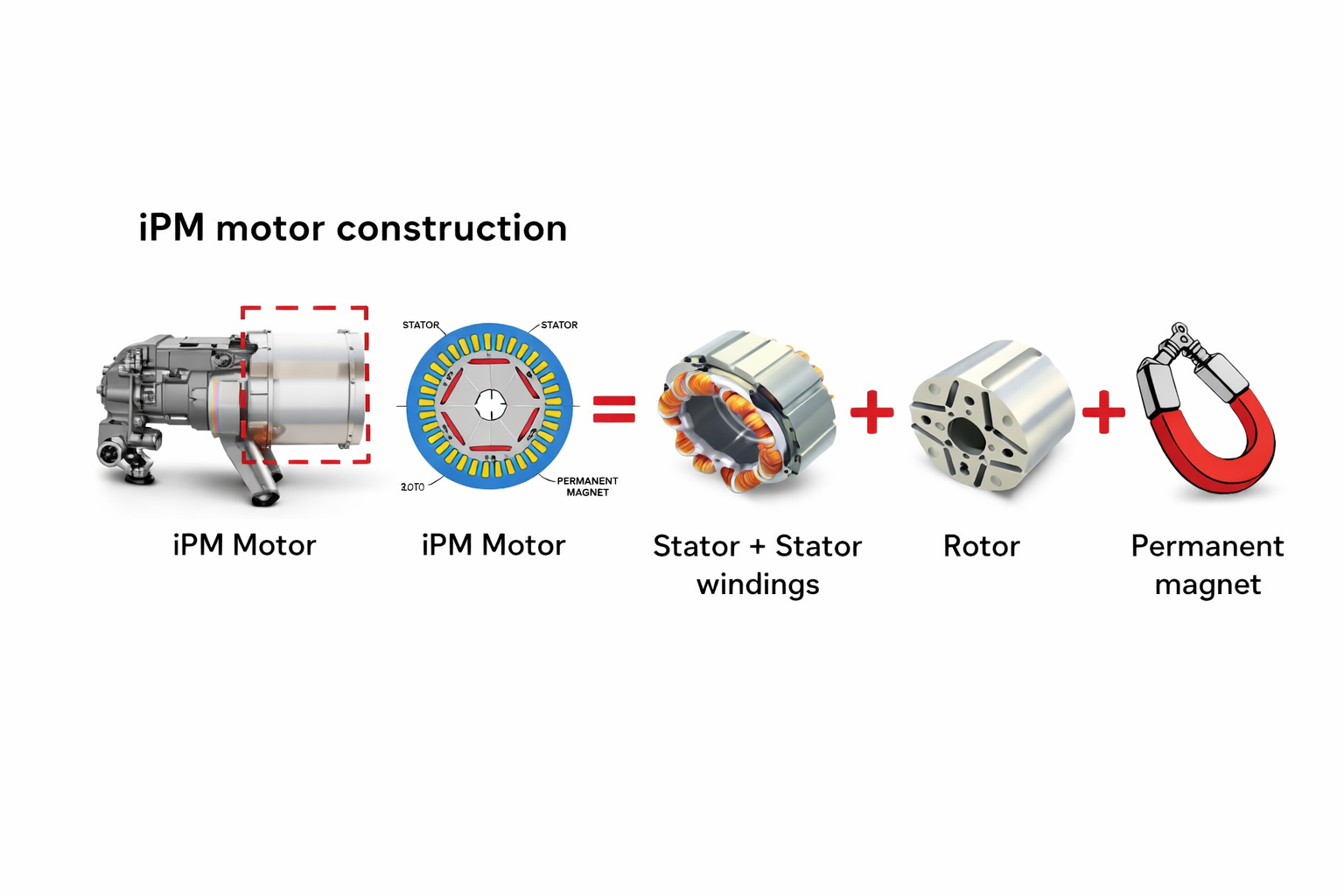

Working Principle: iPM Motor

iPM motors use interior permanent magnets and intelligent control to deliver high efficiency, stable torque, and smoother operation.

-

1

Permanent magnets are housed inside the rotor (interior permanent magnet design).

-

2

Electrical current flows in the stator windings, creating a rotating magnetic field.

-

3

The rotor’s magnets are attracted to this field and rotate with it, producing efficient motion and torque.

IE4 Super Premium Efficiency iPM Motor

Achieve up to 5% energy savings versus traditional IE2 / IE3 induction motors in CPMV—helping reduce operating cost while maintaining stable performance.

Latest-Generation Variable Speed Performance

Oil-cooled direct drive with inverter + iPM motor technology—built for heavy-duty industrial use with a strong focus on energy savings, stable pressure, and easier serviceability.

Built for Reliability, Serviceability & Energy Savings

A premium, heavy-duty variable speed solution designed for stable performance, easy maintenance and reduced operating costs—backed by Chicago Pneumatic engineering.

Element Design & Drive Train

Optimized airflow, stable commissioning, and efficient transmission.

- “In-house” latest design for optimized flow rates

- Oil-cooled drive train for durable & stable usage

- Direct-drive configuration for excellent power transmission

- Wide pressure band for better control

Usage-Friendly Design

Compact footprint with quick service access and smarter controls.

- Compact layout saves installation space

- Pre-filtration for cleaner operation

- Quick access for regular service

- Easy-to-clean cooler

- Intelligent controller

- Smart touch controller with RS-485

- Modbus connectivity support

Performance

Lower losses, higher savings, smoother pressure and airflow.

- Designed for maximum energy savings

- Minimum transmission loss

- Best-in-class inverter with integrated control

- High-technology iPM motor for premium performance

Features that deliver higher efficiency & easier service

A quick visual overview of the CPMV/CPVS iPM technology highlights—built to reduce energy usage and improve uptime.

⤢ View Full Image

⤢ View Full Image

CPMV iPM Range Specifications

Quick reference table for model, pressure, motor, capacity, noise level, weight, connection, and dimensions.

| Model | Pressure (bar) | Motor (HP) | Motor (kW) | Capacity (CFM) | Noise dB(A) | Weight (kg) | Connection | Dimensions L×W×H (mm) |

|---|---|---|---|---|---|---|---|---|

| CPMV 10 PM | 7–10 | 10 | 7.5 | 7–41 | 73 | 205 | 3/4" | 850×750×1000 |

| CPMV 15 PM | 7–10 | 15 | 11 | 10–61 | 73 | 205 | 3/4" | 850×750×1000 |

| CPMV 20 PM | 7–10 | 20 | 15 | 17–73 | 73 | 205 | 3/4" | 850×750×1000 |

| CPMV 25 PM | 7–10 | 25 | 18.5 | 21–114 | 73 | 280 | 1" | 950×850×1080 |

| CPMV 30 PM | 7–10 | 30 | 22 | 26–130 | 73 | 290 | 1" | 950×850×1080 |

| CPMV 40 PM | 7–10 | 40 | 30 | 49–187 | 76 | 362 | 1 1/2" | 1130×950×1200 |

| CPMV 50 PM | 7–10 | 50 | 37 | 65–226 | 77 | 416 | 1 1/2" | 1723×980×1600 |

| CPMV 60 PM | 7–10 | 60 | 45 | 62–301 | 72 | 866 | G1 1/2 | 1723×980×1600 |

| CPMV 75 PM | 7–10 | 75 | 55 | 65–389 | 76 | 1221 | G2 | 1950×1090×1600 |

| CPMV 100 PM | 7–10 | 100 | 75 | 95–463 | 77 | 1285 | G2 | 1950×1090×1600 |

CPVS iPM Range Specifications

Model-wise technical overview for pressure, motor, capacity, noise, weight, connection, and dimensions.

| Model | Pressure (bar) | Motor (HP) | Motor (kW) | Capacity (CFM) | Noise dB(A) | Weight (kg) | Connection | Dimensions L×W×H (mm) |

|---|---|---|---|---|---|---|---|---|

| CPVS 10 PM | 7–13 | 10 | 7.5 | 11–43 | 73 | 230 | 3/4" | 1100×850×1080 |

| CPVS 15 PM | 7–13 | 15 | 11 | 16–64 | 73 | 231 | 3/4" | 1100×850×1080 |

| CPVS 20 PM | 7–13 | 20 | 15 | 22–77 | 73 | 241 | 3/4" | 1100×850×1080 |

| CPVS 25 PM | 7–13 | 25 | 18.5 | 30–121 | 73 | 313 | 1" | 1100×850×1080 |

| CPVS 30 PM | 7–13 | 30 | 22 | 34–136 | 73 | 321 | 1" | 1100×850×1080 |

| CPVS 40 PM | 7–13 | 40 | 30 | 50–200 | 74 | 412 | 1 1/2" | 1330×950×1200 |

| CPVS 50 PM | 7–13 | 50 | 37 | 67–227 | 73 | 413 | 1 1/2" | 1330×950×1200 |

| CPVS 60 PM | 7–13 | 60 | 45 | 70–308 | 70 | 906 | G1 1/2 | 1723×980×1600 |

| CPVS 75 PM | 7–13 | 75 | 55 | 57–401 | 74 | 1461 | G2 | 2259×1060×1594 |

| CPVS 95 PM | 7–13 | 100 | 75 | 60–470 | 75 | 1535 | G2 | 2259×1060×1594 |

The One-Stop Solution

Latest-generation iPM + inverter technology designed for heavy-duty industrial use—focused on energy savings, stable pressure, and easier serviceability.

Latest Variable Speed Technology

- Perfectly matches air supply to air demand

- No unload losses as for fixed-speed compressors

- Narrower pressure band → lower working pressure

- No peak current at startup → no penalties

Calculate your savings and show them the way up to your bank!

Introducing the Future of Air Audits – “Airchitect”

- Up to 35% energy losses due to unload

- Every 1 bar drop in pressure output results in around 7% energy savings

- Older installations have leakages up to 20%

ROOM

PROFILE

Complete Peace of Mind

with AirXtend Warranty

Have complete confidence in your compressor with AirXtend, the extended warranty plan for Screw Elements—designed to protect performance, efficiency, and long-term reliability.

- Extended warranty on screw elements

- Maintains system efficiency & prevents pressure loss

- Genuine Chicago Pneumatic spare parts only

- Reduced downtime & lower operating costs

- Priority support during urgent breakdowns

Industrial Air Compressor Solutions in Pune

Airline Engineering Company provides industrial air compressor sales, service, rentals, and AMC support in Pune and surrounding industrial areas. Our solutions are designed to support manufacturing units, engineering companies, and infrastructure projects with reliable compressed air systems.

Where Trust Meets Engineering Excellence

Our customers trust us for honest recommendations, reliable products, and consistent service support. We focus on long-term value rather than short-term sales, ensuring every solution we deliver aligns with customer requirements and operational goals.

Honest Recommendations

We suggest only what fits your actual airflow and pressure needs—no oversizing or unnecessary upgrades.

Reliable Performance

Solutions designed for stable output, higher uptime, and dependable daily production support.

Transparent Communication

Clear service updates, practical guidance, and straightforward information you can rely on.

Long-Term Value

We prioritize lifecycle savings—efficient systems, genuine spares, and strong service support.