CP / CPE / CPF Industrial Screw Air Compressors (110–355 kW)

High-Performance Air & Water-Cooled Screw Compressors

The CP, CPE, and CPF rotary screw air compressor series from Chicago Pneumatic are engineered for heavy-duty industrial environments requiring continuous operation, high airflow, and maximum reliability. Available in fixed-speed and inverter-driven (VSD) configurations, these compressors deliver optimized productivity with reduced energy consumption.

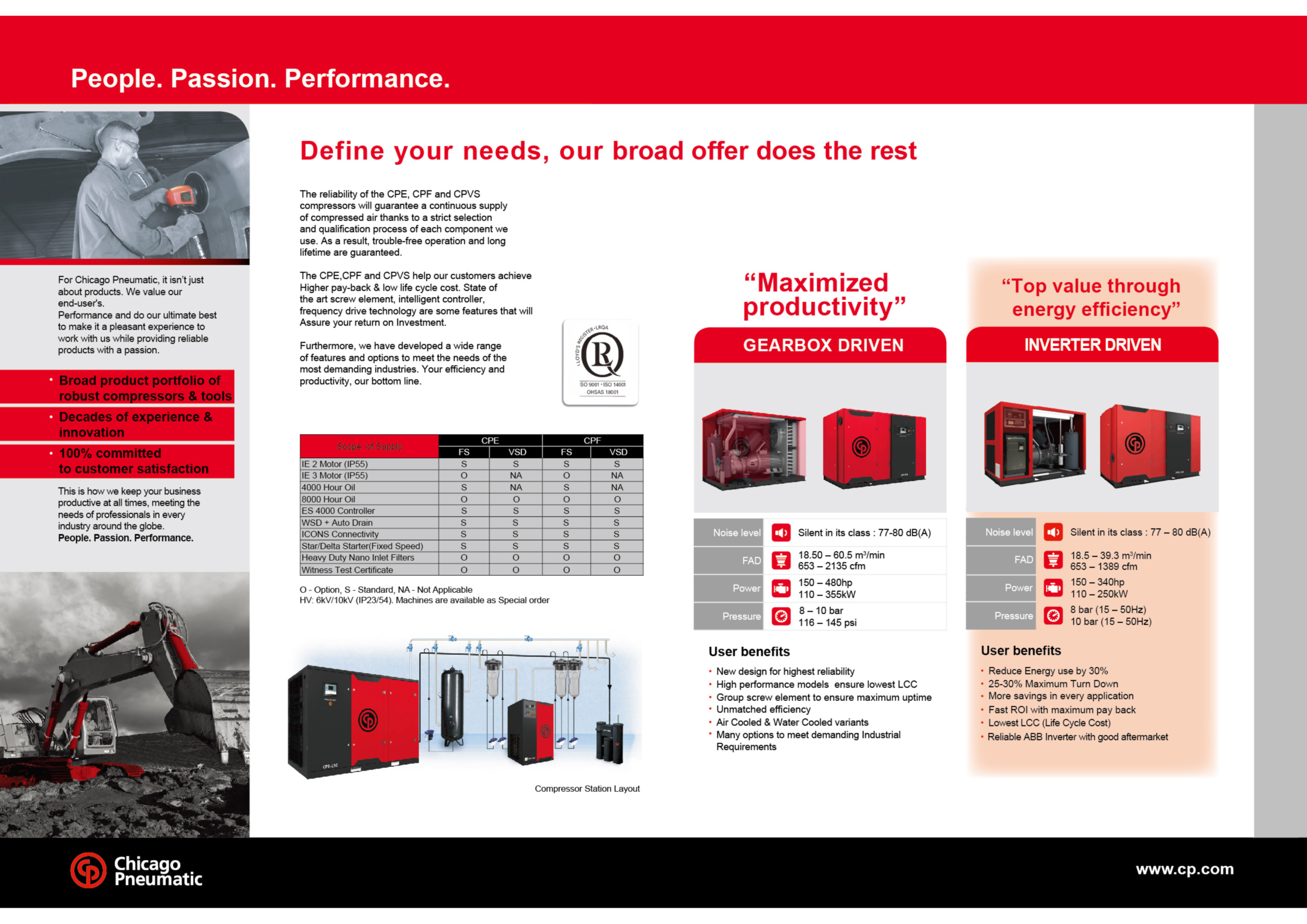

Product Range (CP / CPE / CPF / CPVS)

CP Series Fixed Speed Compressors

- Reliable gearbox-driven technology

- Optimized for constant air demand

- Ideal for stable production environments

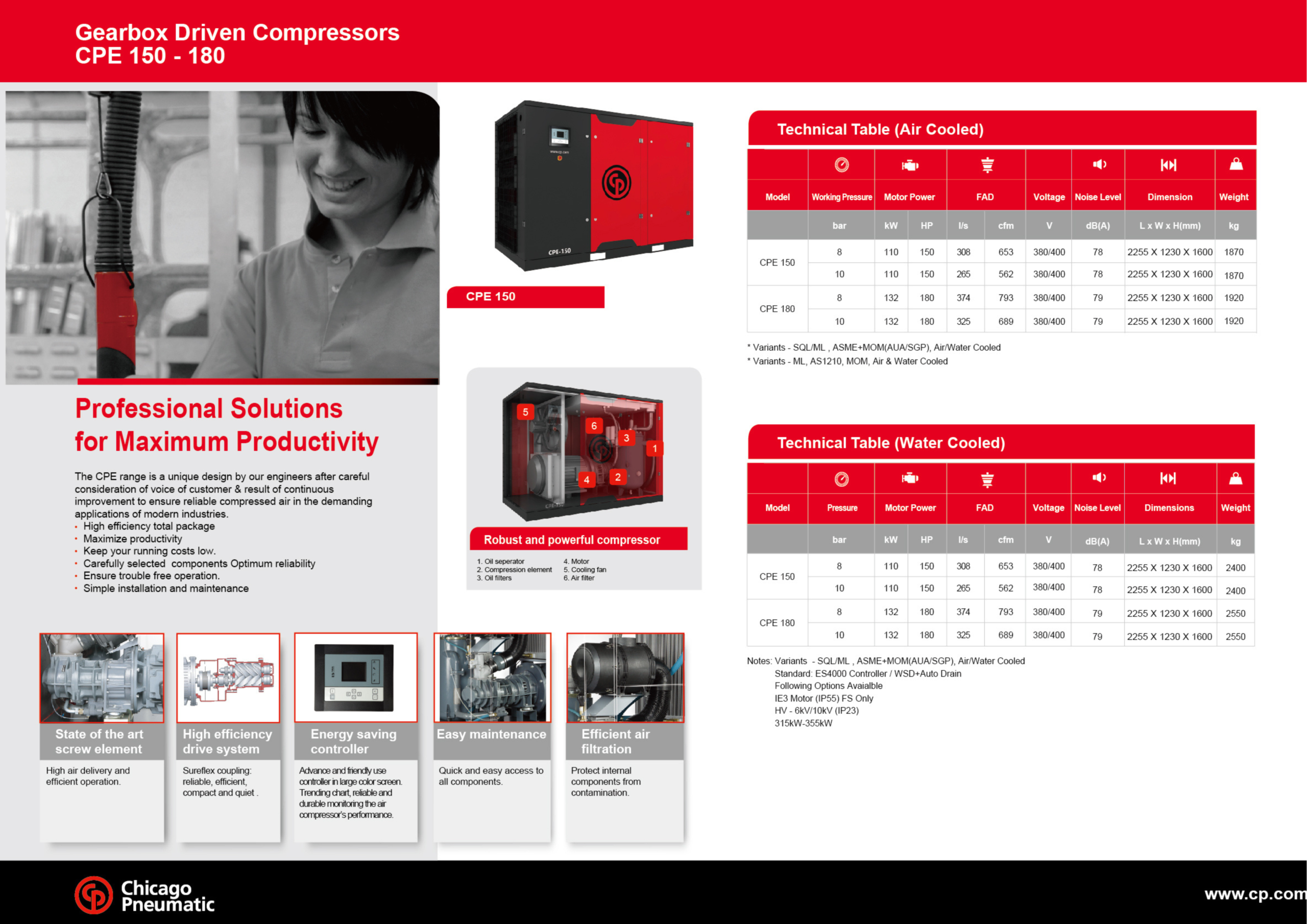

CPE Series Enhanced Fixed Speed

- Improved efficiency and cooling

- Modular architecture

- Lower operating costs

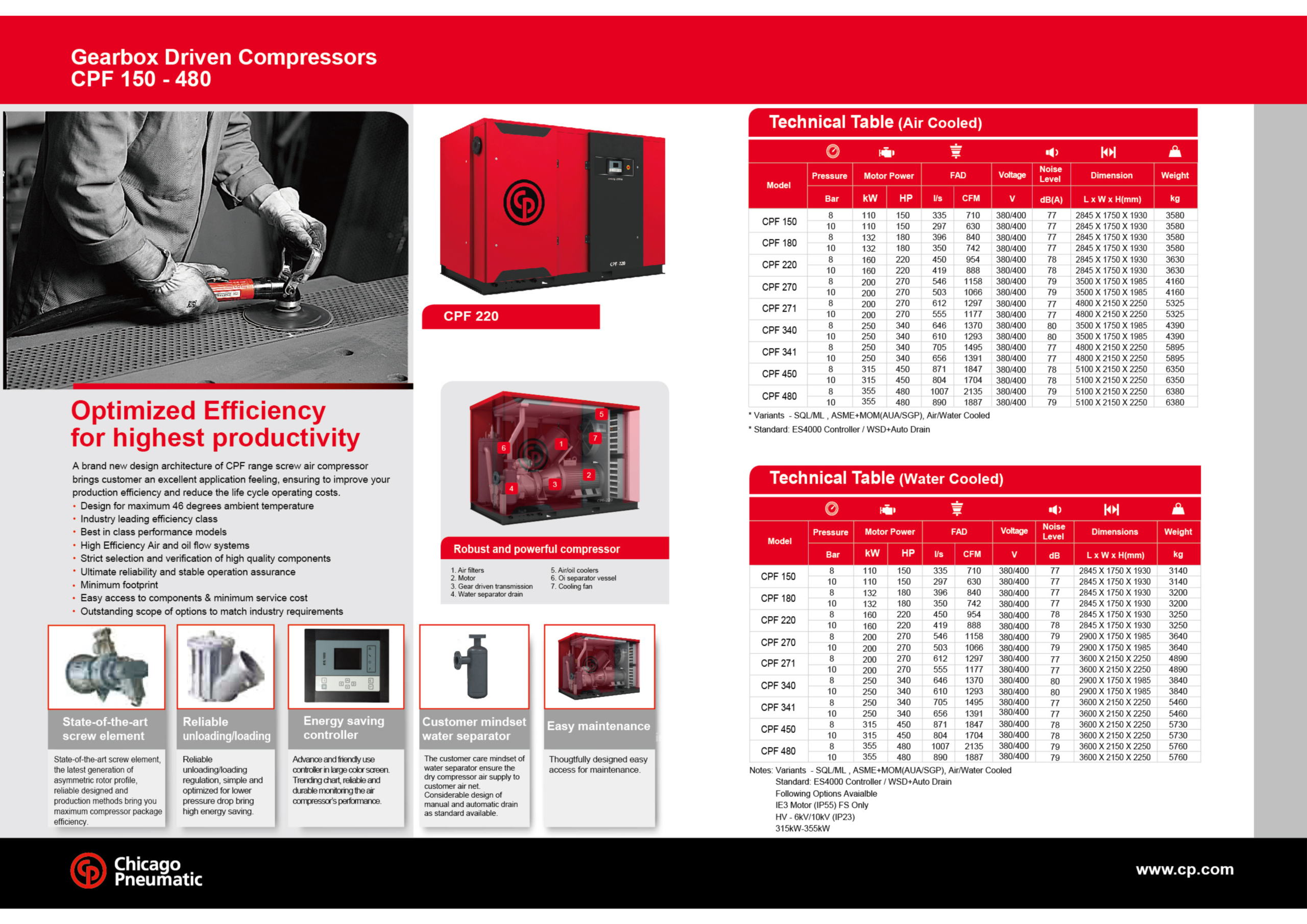

CPF Series High-Capacity Fixed Speed

- Heavy-duty performance up to 355 kW

- Robust design for harsh environments

- Designed for maximum uptime

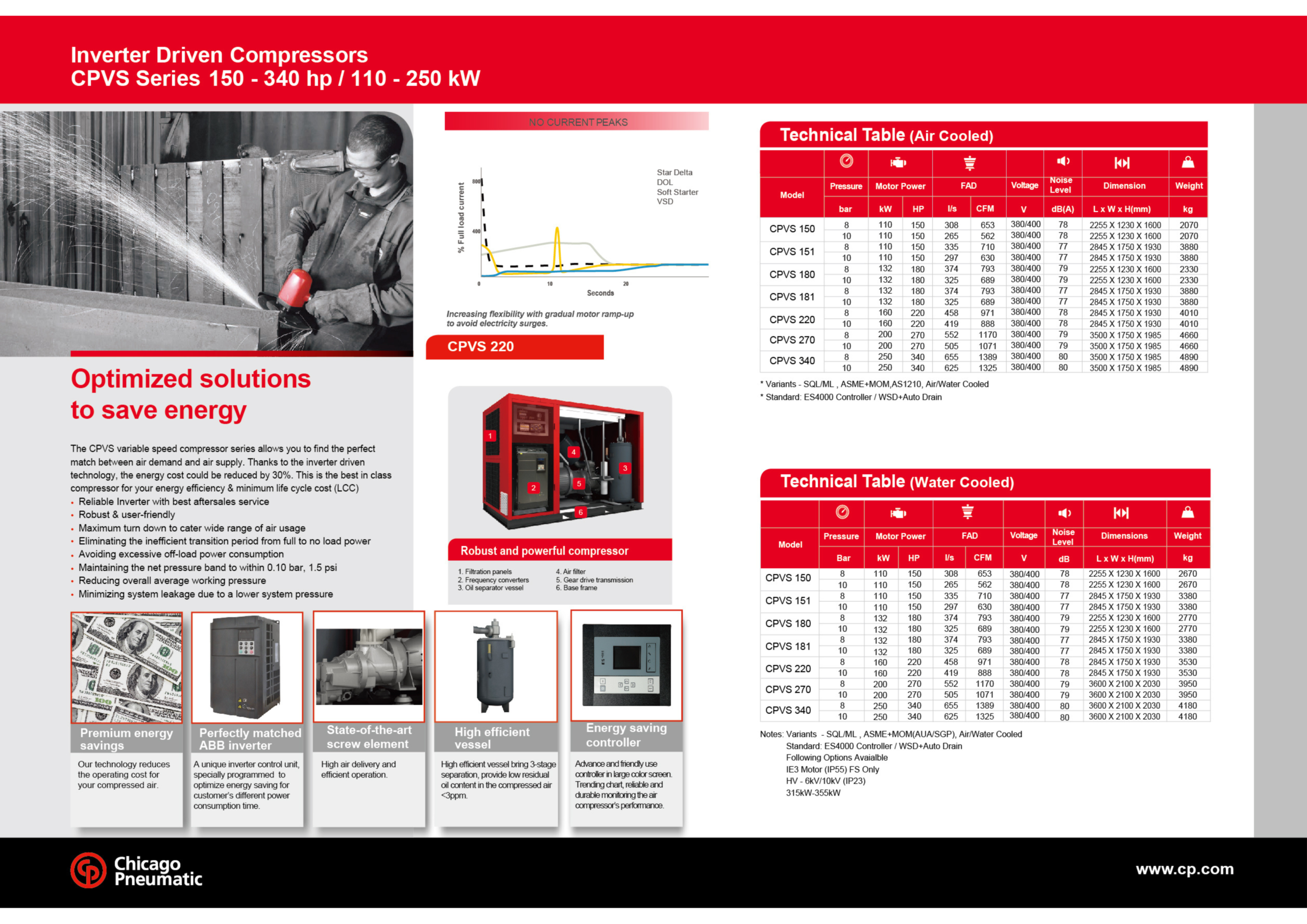

CPVS Series Inverter Driven (VSD)

- Matches air output to demand

- Up to 30% energy savings

- Reduced load/unload losses

Key Features & Benefits (Product Advantages)

Maximum Productivity

- Gearbox-driven screw element

- Optimized airflow and pressure stability

- Continuous duty performance

Energy Efficiency

- Variable Speed Drive (VSD) options

- Reduced power consumption during partial load

- Lower total cost of ownership (TCO)

Air & Water-Cooled Options

- Designed for tropical & high-ambient conditions

- Stable operation in demanding environments

Easy Maintenance

- One-side service access

- Modular components

- Reduced service time and downtime

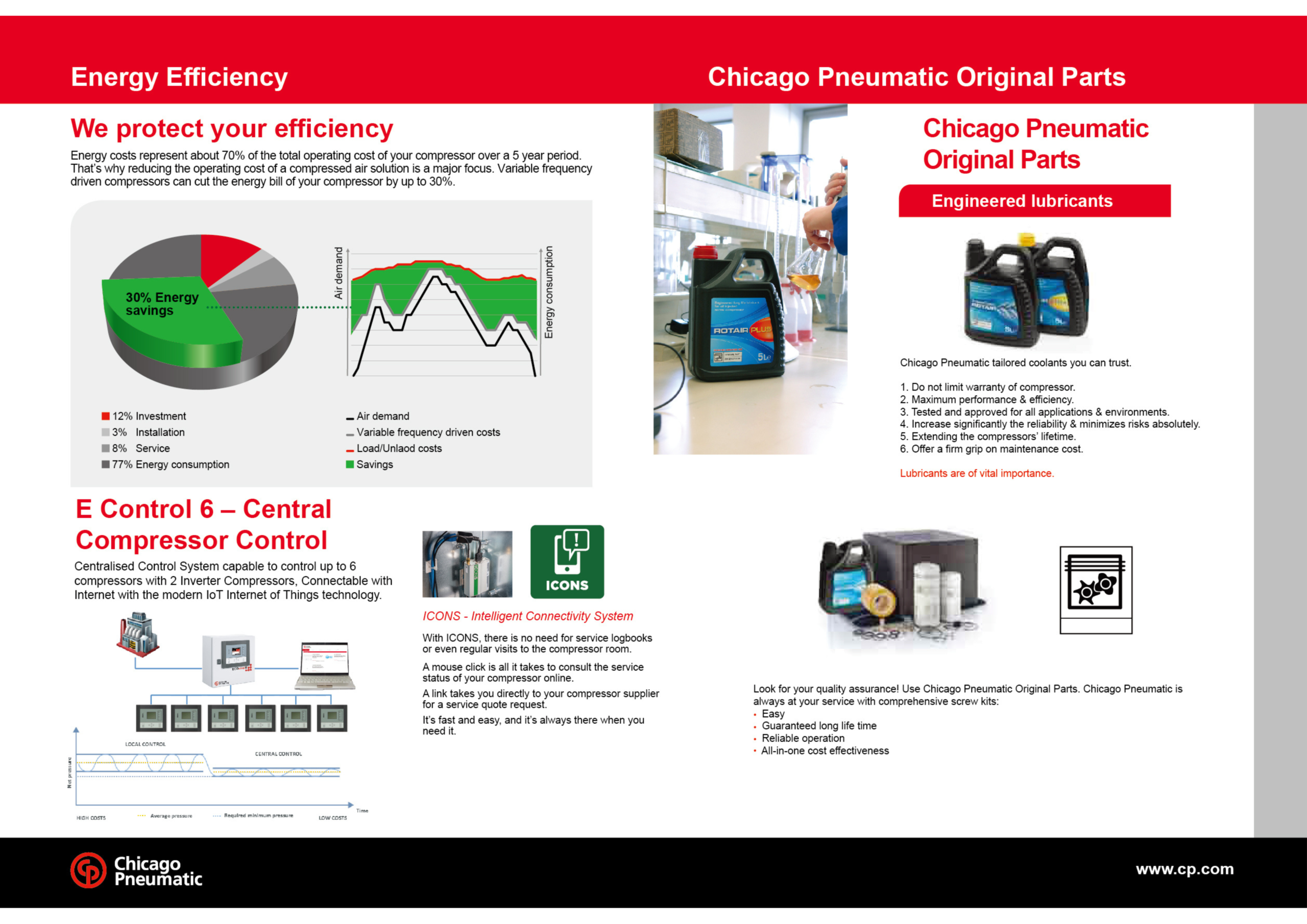

Smart Control & Connectivity

- ES 4000 / E-Control 6 controllers

- Centralized control of up to 6 compressors

- IoT-ready for remote monitoring

Technical Overview (SEO-Optimized)

Power Range

110 – 355 kW (150 – 340 HP)

Cooling Type

Air-cooled & Water-cooled

Pressure Range

8 – 13 bar

Drive Type

Gearbox / Inverter (VSD)

Installation

Floor-mounted

Voltage

380–415V / 50Hz

Energy Efficiency & Sustainability (Lifecycle Savings)

Why Efficiency Matters

Energy represents nearly 70% of a compressor’s lifecycle cost. Chicago Pneumatic’s inverter-driven solutions help reduce operating costs while supporting sustainability targets.

Inverter-Driven Impact

- Energy consumption reduced by up to 30%

- CO₂ emissions reduced significantly

- Lower load/unload losses during variable demand cycles

Applications (SEO Keywords)

Need the Right Air Compressor for Your Industry?

Our experts will help you select the most efficient and cost-effective air compressor solution based on your application and usage requirements.