CPZ Quality Air Solutions by Chicago Pneumatic

Chicago Pneumatic CPZ Quality Air Solutions are engineered to protect compressed air systems from moisture, oil, particles, and contaminants that can damage equipment and reduce production efficiency. Designed for industrial environments, CPZ refrigerant dryers and air treatment solutions deliver clean, dry, and reliable compressed air, improving productivity while extending the service life of downstream equipment.

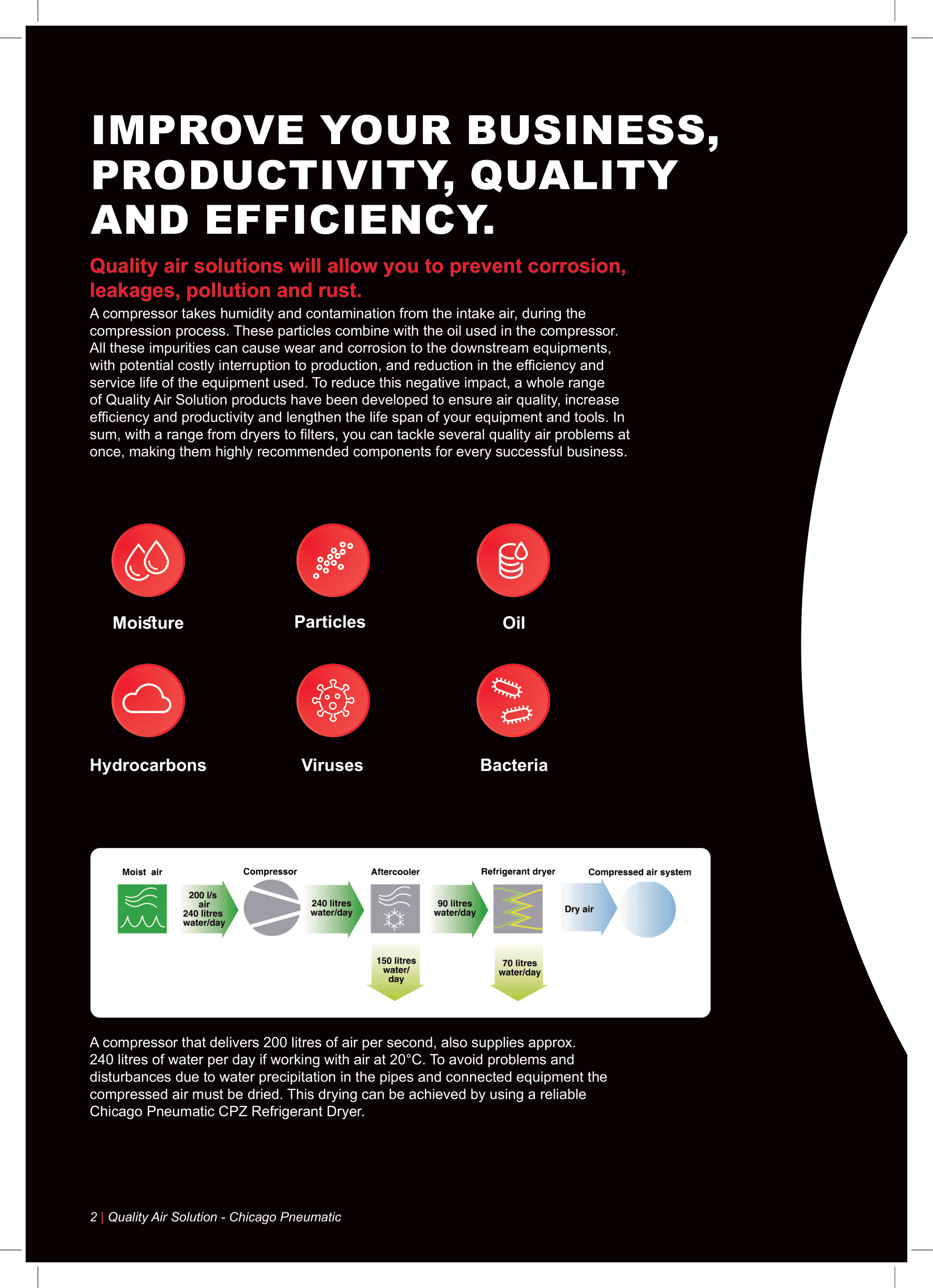

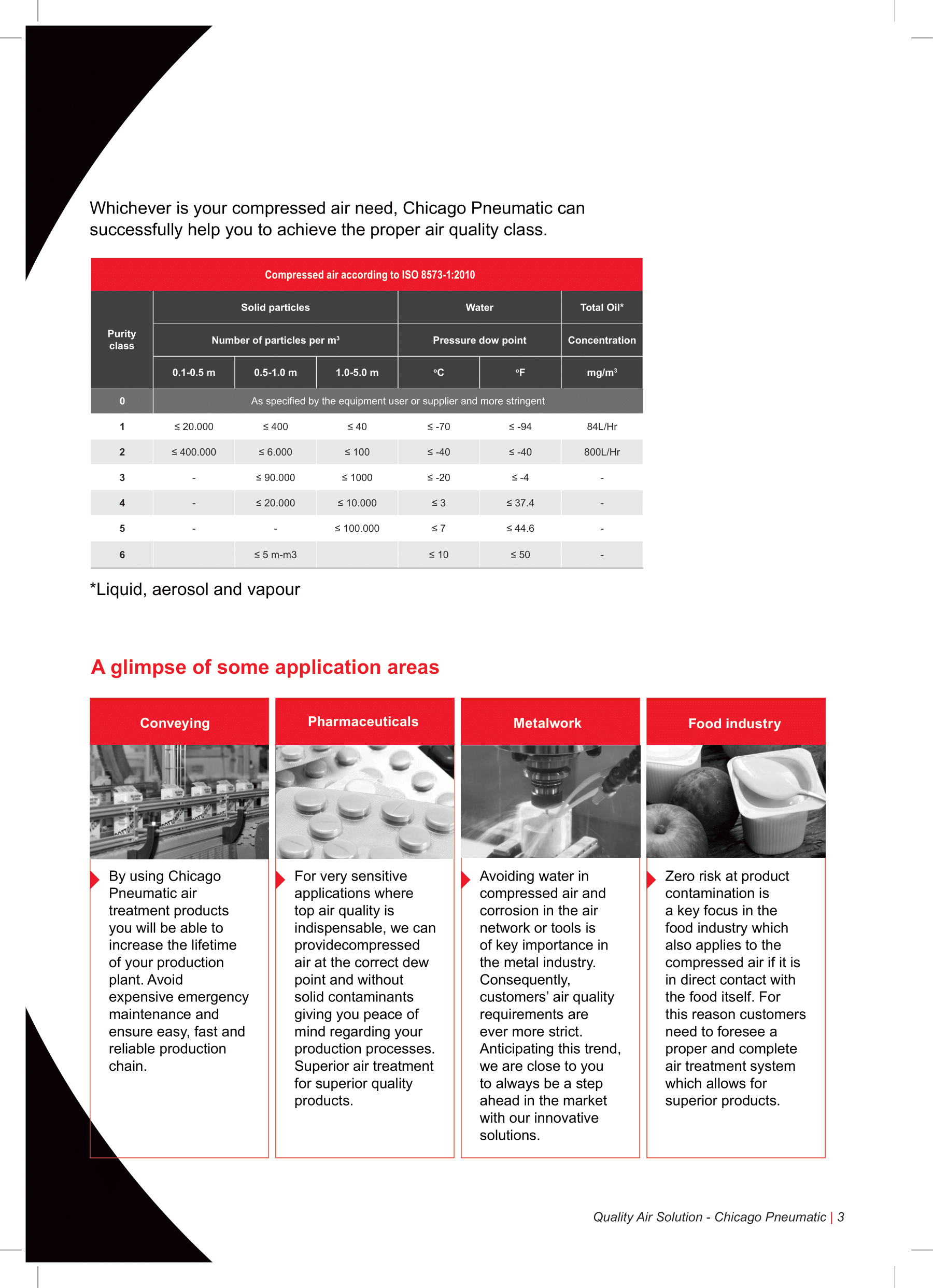

Quality air treatment is essential because compressed air naturally contains humidity, hydrocarbons, particles, oil vapors, bacteria, and viruses—which can cause corrosion, leakage, rust, and costly production downtime if not properly treated.

Why Quality Air Matters in Compressed Air Systems

A compressor delivering 200 liters of air per second can introduce up to 240 liters of water per day into the compressed air system under typical conditions. Without proper drying and filtration, this moisture leads to:

- Corrosion in pipelines and tools

- Reduced efficiency of pneumatic equipment

- Increased maintenance and energy costs

- Risk of product contamination

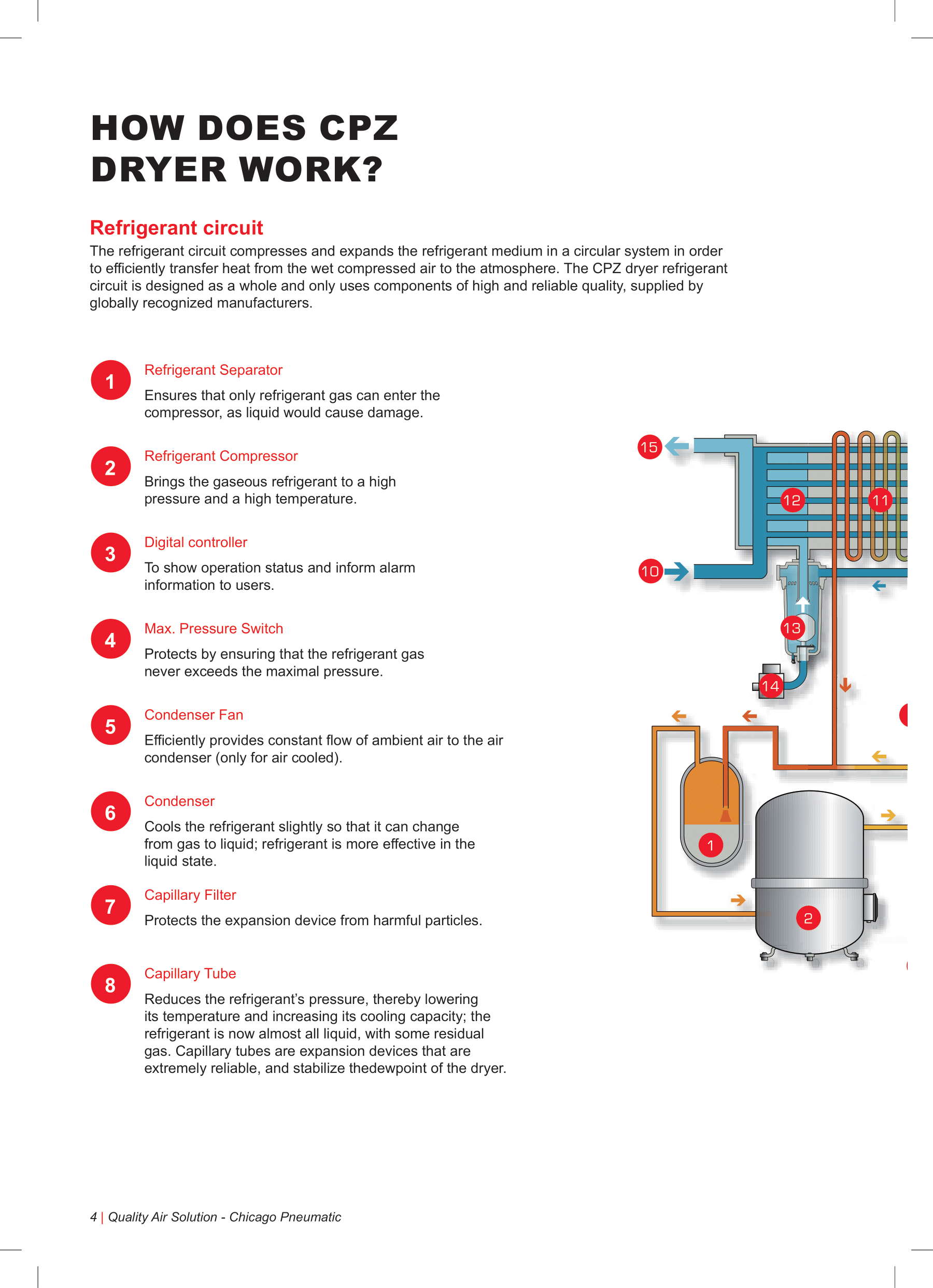

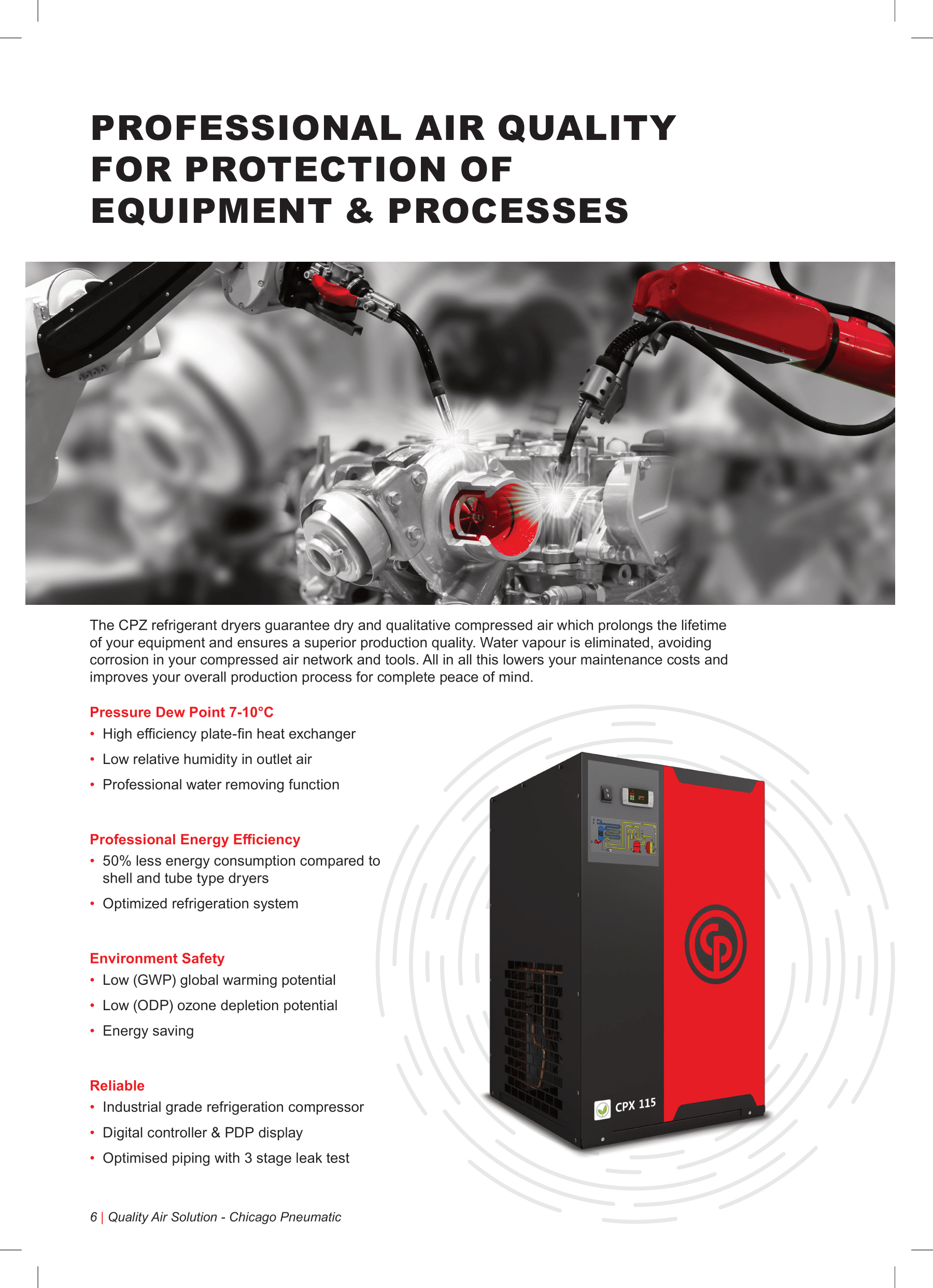

CPZ Refrigerant Dryers – Key Features & Benefits

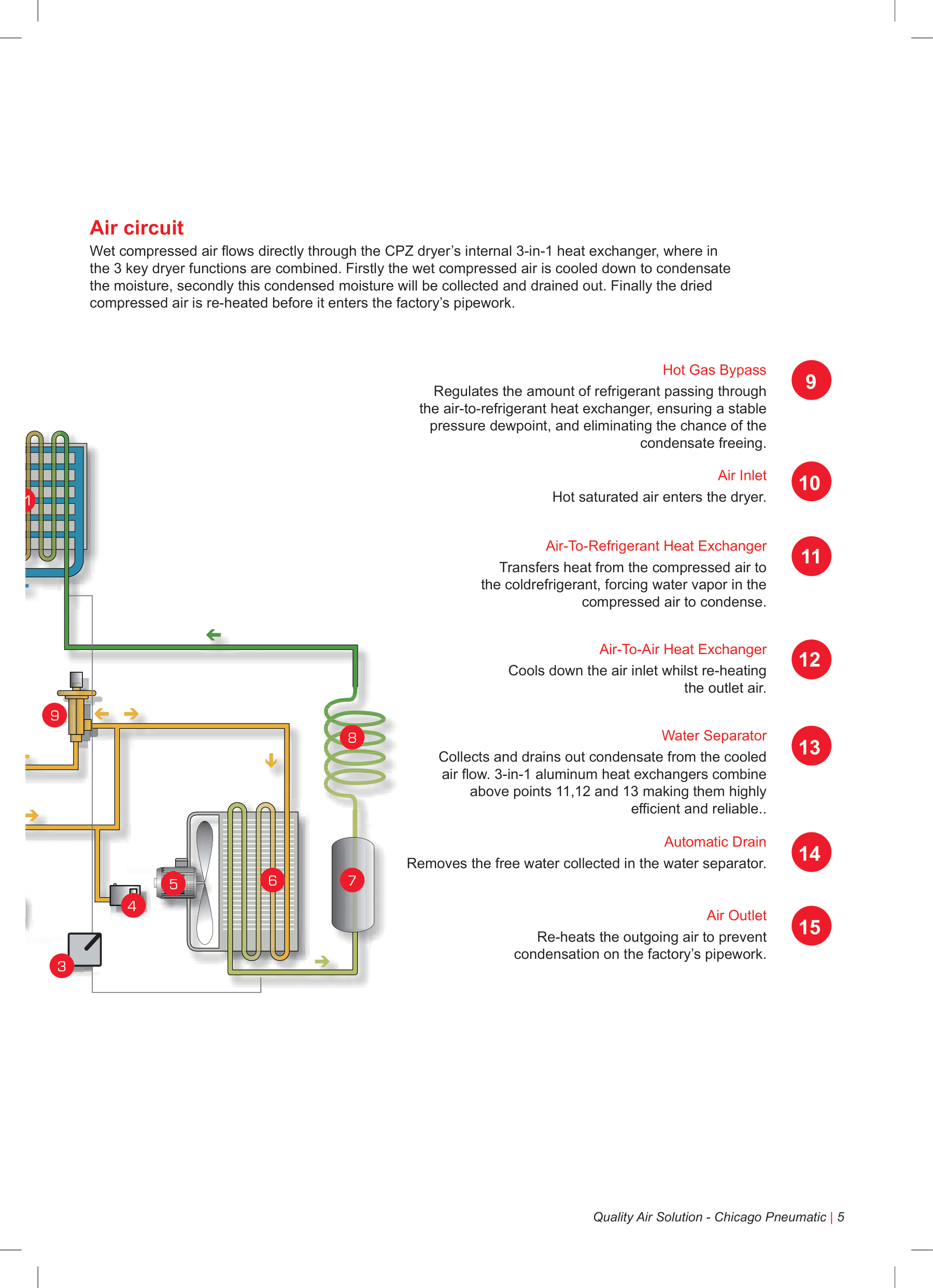

Reliable Moisture Removal

CPZ dryers ensure a stable pressure dew point of 7–10°C, preventing water precipitation inside compressed air lines and equipment.

High Energy Efficiency

- Up to 50% lower energy consumption compared to shell-and-tube dryers

- Optimized refrigeration system for consistent performance

- Reduced pressure drop for energy savings

Robust & Industrial-Grade Design

- High-efficiency plate-fin heat exchanger

- Industrial-grade refrigeration compressor

- Durable canopy for safe installation in harsh environments

Advanced Control & Monitoring

- Digital electronic controller with PDP display

- Real-time monitoring of dryer operation and dew point

- Alarm and protection functions for safe operation

Environmentally Responsible Operation

- Low GWP (Global Warming Potential) refrigerants

- Low ODP (Ozone Depletion Potential)

- Energy-efficient and sustainable air treatment solution

Applications

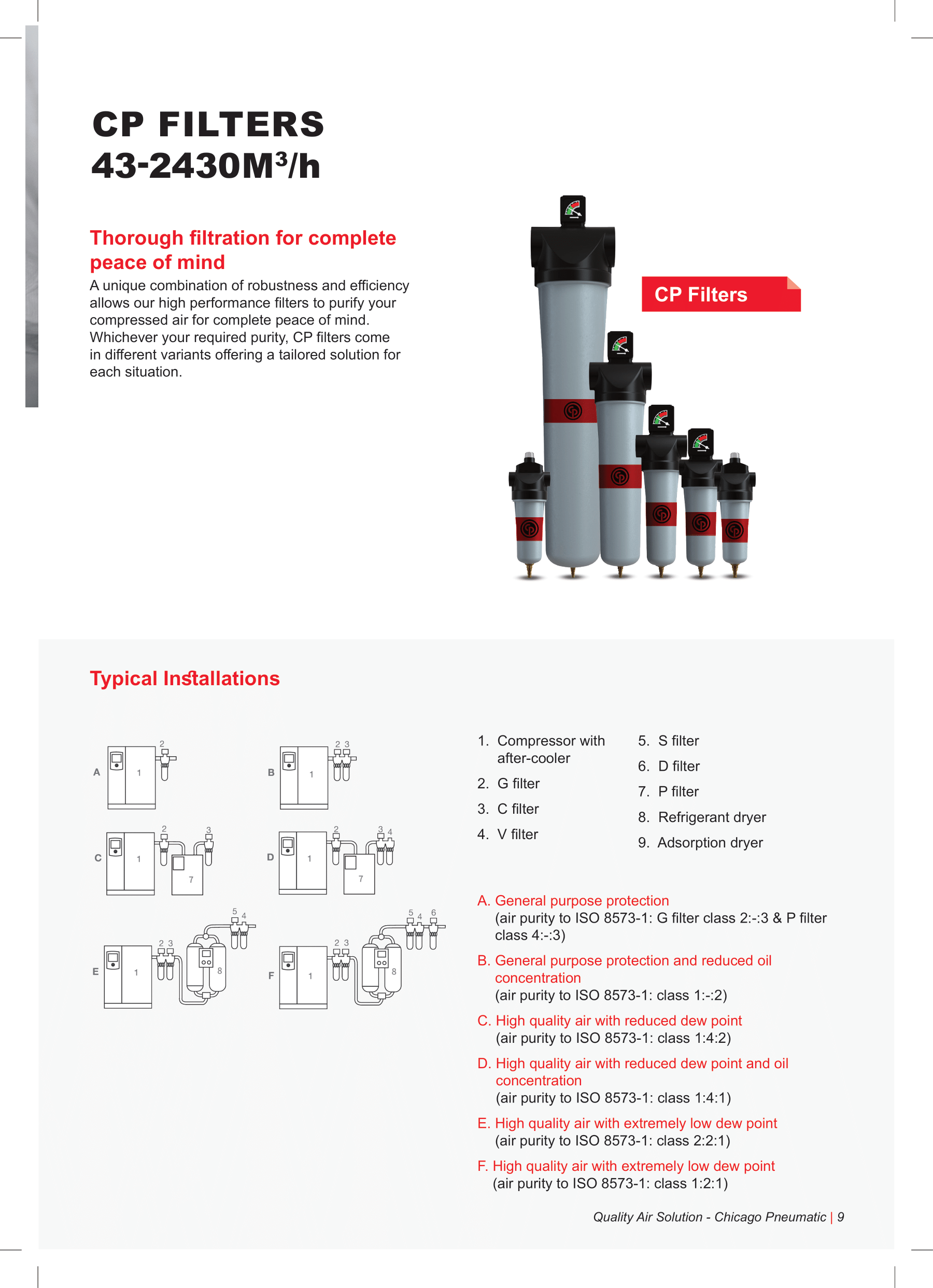

CPZ Quality Air Solutions are engineered for industries where clean, dry compressed air is essential for product quality, operational reliability, and long-term equipment protection.

- Manufacturing and engineering industries

- Pharmaceutical production

- Food & beverage processing

- Metalworking and fabrication

- Electronics and precision industries

- Automotive and assembly plants

Why Choose Chicago Pneumatic Quality Air Solutions

120+ Years of Expertise

With over 120 years of compressed air expertise, Chicago Pneumatic delivers globally proven air treatment solutions trusted across industries worldwide.

Robust & Reliable Engineering

CPZ systems are designed for continuous industrial operation, offering reliable moisture control and long service life.

Energy-Efficient Operation

Optimized dryer design and reduced pressure drop help lower energy consumption and operating costs.

Strong Service & Support Network

Supported by a strong global and India-wide service network, CPZ solutions ensure maximum uptime and long-term reliability.